Reducing Systematic Errors in Laser Flash Method Caused by Detector Inherent Delayed Response

- Contact:

S. Breuer

F.R. Schilling

- Startdate:

2017

- Enddate:

2020

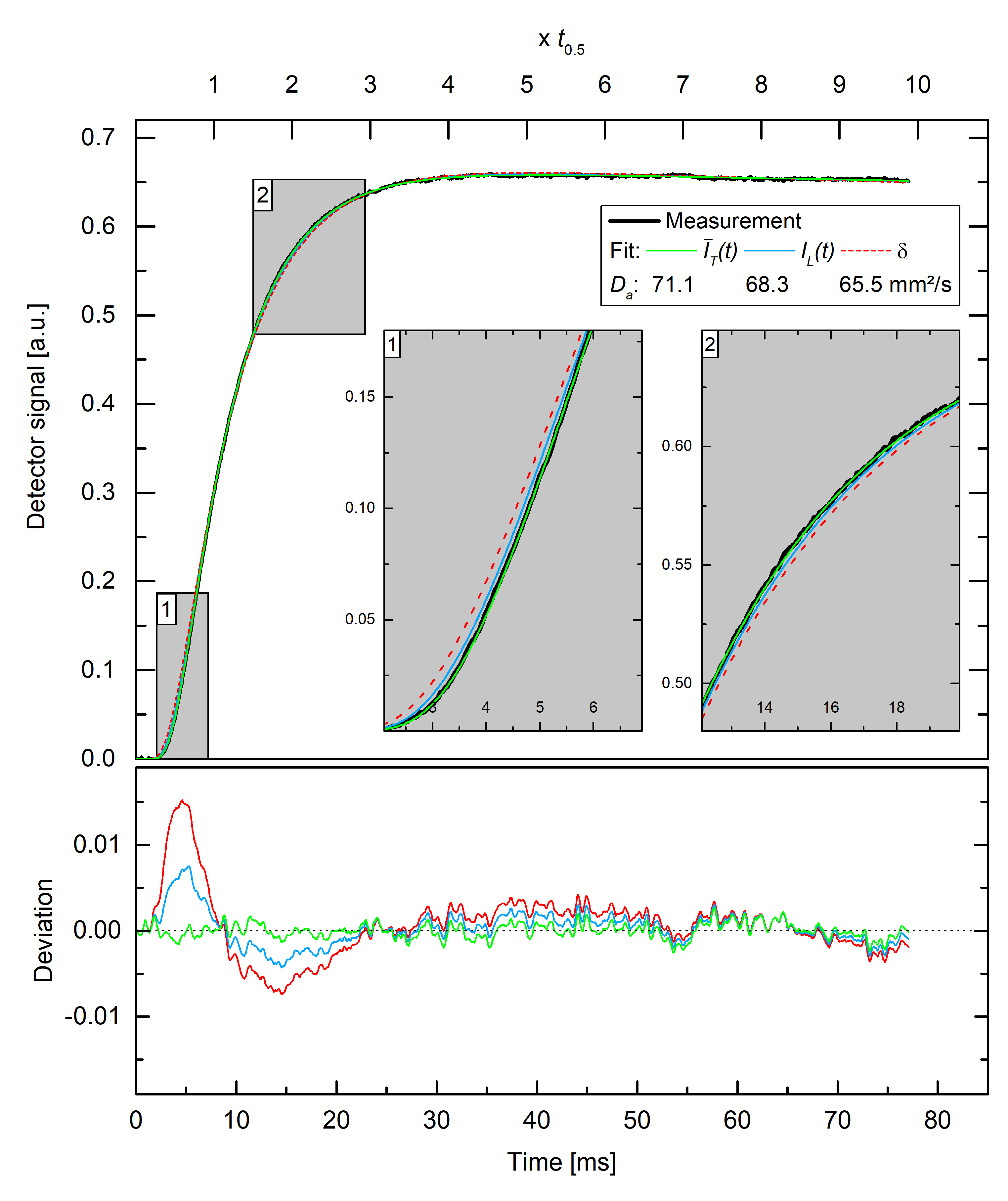

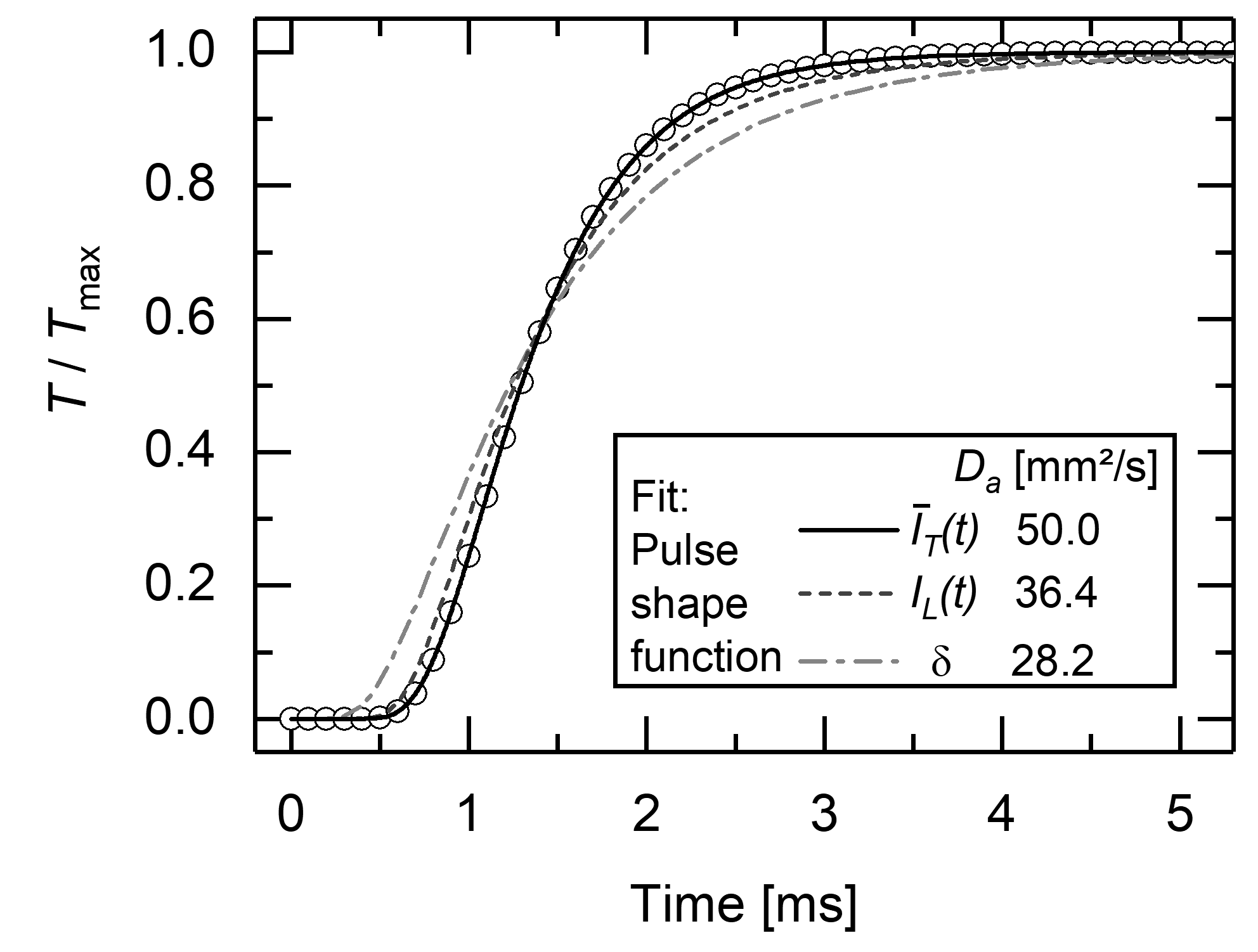

Laser flash apparatuses (LFA) are a widely used method to determine thermal diffusivity. Different factors influencing the quality of the diffusivity determination have been identified. Especially for thin samples, detector related time delays between the triggering of a laser pulse and signal detection as well as the shape of the laser pulse may become crucial for precise measurements.

It is well known how to detect and account for laser pulse shape with respect to the trigger signal ("finite pulse-time effect"). An additional delayed response of the signal can be caused by detectors and electronic components (e.g. electronic filters) and inherent to LFA measurements. To correct for this possible additional delay, the detector signal of direct laser pulses are measured and a transfer function may be derived. This would allow to account for the laser-pulse-detector behavior, based on the measured characteristic of the laser for different detectors (indium antimonide (InSb) and MCT (HgCdTe) detectors).

The effect of the detector response is detector specific. For the experimental setup used, systematic errors caused by this effect could be in the same range than the often considered finite pulse-time effect. To consider the actual pulse shape including the detector-sided retardation effect, a data evaluation routine based on the principles of superposition gets developed. It should include a transfer function to adapt the detector signal using the pulse shape measured by a diode within the apparatus. With this, the finite pulse-time effect as well as the detector-sided retardation will be considered and these systematic errors get effectively reduced. To avoid additional experimental uncertainties for the study, synthetic temperature response data are used to determine the systematic errors for various thermal diffusivities and sample thicknesses.

POCO Graphite thermal diffusivity measurement with data evaluation according to different laser pulse functions (left), synthetic thermal diffusivity temperature history with different laser pulse shape functions used for modeling (right)