Well Logging Technology

Well logging tools are electronic measuring devices which are lowered into an open borehole to determine petrophysical properties of rocks exposed at the borehole wall. The data provide essential information about the stratigraphy, lithology, and potential subsurface reservoirs. The technology is widely applied in subsurface resources exploration and production. Depending on the inclination of the well, the logging tools are run into the wellbore by a wireline or by a conventional drillpipe. At the beginning of a logging run, which starts at the bottom of the wellbore, the measuring pads of the tool are brought in contact with the borehole wall. While pulling the logging tool to the surface by a winch, the pads measure physical properties of the rocks like borehole shape and diameter, electrical resistivity, electrical conductivity, acoustic (sonic) velocity, radioactivity. Specific tools are equipped with a radioactive source which locally expose rocks to gamma radiation to obtain information about porosity, minerals, water, solubles, and hydrocarbon fluids within the pores.

Although well logging is a well-established technology in the oil, gas and coal industry as well as in hydrogeology since the nineteen-twenties, new areas of application are currently under development. The Petrophysics Working Group at KIT is specialized in the application of logging technologies for rock mechanics and subsurface stress characterization. Deployment areas are development and surveillance of reservoir dams, underground storages for hydrogen, as well as geothermal and groundwater resources. The logging data are also applied for calibration of numerical earth models and simulation of subsurface deformation processes.

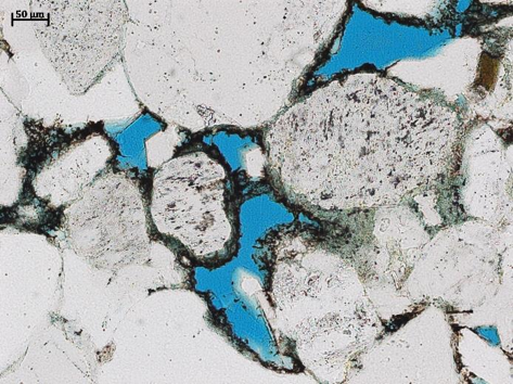

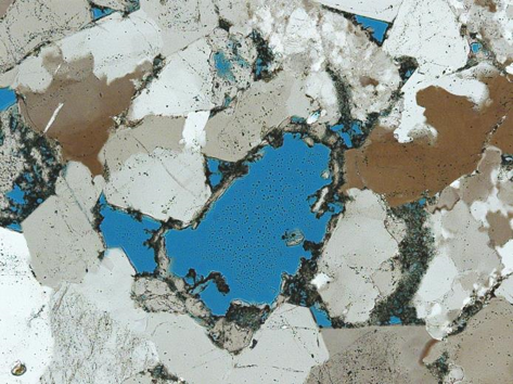

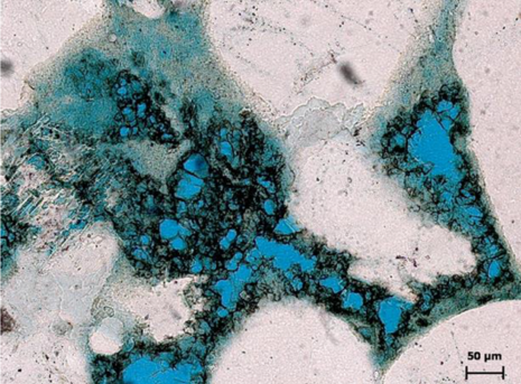

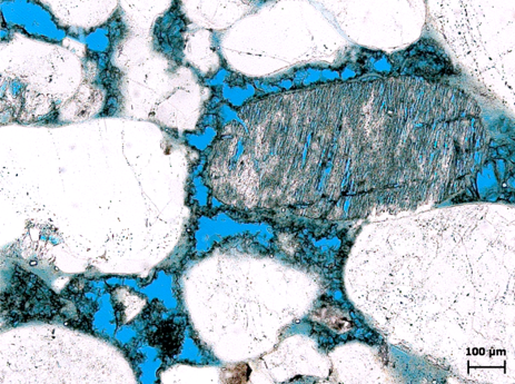

Micro-fabrics and Porosity of a Reservoir Sandstone

Logging technologies can measure and characterized the fabrics, mineral assemblages, the porosity and the pore fill from a wellbore wall without taking physical samples from subsurface. Hence this technology is much cheaper and less time-consuming than sample assessment in the laboratory

|

|

|

|

We are currently operating the listed tools and auxiliary equipment

| Tool | Tmax (°C) | Formation Property |

|---|---|---|

| Gamma-Ray (GR) | 70 | Formation Gamma Radiation: 40K, 232Th, 238U, 235U, 234U |

| Resistivity (RES) | 70 | Formation Resistivity |

| Oriented 4-Arm Caliper (CAL) | 70 | Wellbore Diameter, Shape & Dip |

| Temperature (TEMP) | Mud & Formation Temperature | |

| Conductivity (SP) | Mud & Formation Fluid Salinity | |

| Spinner Flow Meter | Fluid Flux | |

| Full Wave Form Sonic (DT) | Acoustic Slowness, Acoustic Travel Time | |

| Acoustic Televiewer | 70 | Fractures, Breakouts, Caverns |

| Optical Televiewer | Sedimentary Structures & Joints | |

| Nuclear Magnetic Resonance (NMR) | Pore Size Distribution, Porosity (Permeability), Fluid Types |

Logging Trailer

Borehole logging tools are operated from a trailer-based control and data acquisition lab with wellsite data processing resources and internet link. The trailer also comprises winches for up to 2000 m of wireline, electric power generator, maintenance equipment, tool and sparepart storage racks, floodlights, mobile all-weather protection shelter, and safety and cleaning kits. It can be hauled by a midsize tansporter vehicle or a small rental lorry.

For wellsite operations, the trailer is moved backward close to the wellhead and locked and stabilized. The logginging tool is connected to the wireline cable and lowered into the wellbore by suspension of a tripod installed over the wellhead.

Final processing, display and print of logging data is based on the ALT software platform.